Label printing is a relatively complex technical work, and it is necessary to understand the knowledge of the relevant printing process. The following is an introduction to the basic process of label printing for your reference.

Label - Product - Film - daily chemical, food

Daily chemical food labels commonly used transparent surface material, frosted surface material, bright silver/matte silver surface material, laser surface material, high penetration no label feeling surface material and many other kinds of labels

Label - Product - Film Category - Shrink Film

The fitted appearance breaks through the traditional label design, creating a 360-degree surround product decoration effect, combined with the glossiness of raw materials, presenting a metallic ink texture. Can be combined with cold stamping, metal ink to bring different close to the label texture of the shrink label.

A variety of simulation testing means to help the brand to quickly shrink film design, important content avoidance. Combined with digital printing, shrink film can be developed and tested quickly.

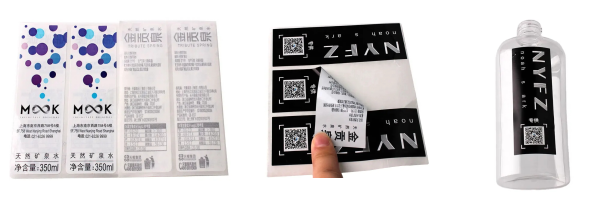

Label - Process - Digital Printing

Save plate making, early sample cost, can achieve rapid proofing, confirm the effect. Achieve design, color separation, proofing, die cutting, confirmation, completed in one day. Anti-counterfeit colour variable QR code data printing, each QR code is different. Achieve variable bacterial pattern fluorescent color printing, counterfeit difficult to copy high coefficient Kaleidoscope realises variations of each pattern to increase consumer interaction.

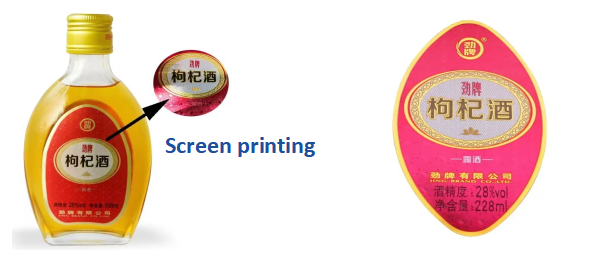

Label - Process - Screen printing

Screen printing: The ink color is rich, the pattern texture is prominent. The pattern printed by screen printing technology is full of ink and the texture is prominent, which is very suitable for printing some products that need to highlight the visual effect of the pattern. Excellent durability, waterproof, sunscreen, not easy to fade.

With online screen printing technology, suitable for mass label production. Precise registration and high efficiency.

Label - Process - Double Sided printing (Multi-layer)

Double-sided printing uses one sheet of paper to encompass the contents of two sheets of paper for single-sided printing, using less paper and being more environmentally friendly.Combining product design and the perspective of different liquids/packages can create some novel packaging experiences.

Tag - Craft - Bump

The advantage of the label punching process is that it can make the label more beautiful, high-grade, textured, increase the added value of the product and brand image.

Label - Process - Multi-type ink

Fluorescent ink: The material used is invisible fluorescent ink, the printing process is simple. The ink prints an invisible pattern or text that presents a clear, bright fluorescent pattern under ultraviolet light. It's very colorful. The anti-counterfeiting detection is convenient, as long as there is an ultraviolet light source or banknote detector.

Fragrance ink: It can combine the product flavor and customize the fragrance printing ink, which can be stored for a long time and release the fragrance when the consumer squeezes or rubbing.

Metal ink: can replace part of the cold stamping, has a strong metal effect, while saving costs, to achieve a similar cold stamping effect.

Color-changing ink: cold change, heat change, UV change.

Label - Process - Anti-counterfeiting & Traceability

Easy to identify: Authenticity can be easily identified through the naked eye, props, mobile phone APP, instruments and other equipment

Patented technology: combined with various patented materials, ink, printing, processing and other technologies to achieve effective protection

Hard to copy: Use the principles of optics and physics to prevent copying

Various applications: With shrinkable sleeve label, anti-unpacking label, suitable for all kinds of materials, strengthen product protection Combined with digital equipment, it can produce various anti-counterfeiting effects such as variable bright code, secret code and variable shading.

Tag - Craft - Naked eye 3D

Through the film process and customized shading, consumers can directly feel the 3D effect, which can be copied with high difficulty and excellent visual effect.

Label - Product - Film - Wine label

Wet and water resistant ice bucket, excellent machine performance, suitable for high-speed labeling equipment.

Different types of labels can be produced on demand: washable, non-washable, non-adhesive coating, 360° ring paste, front and back label with the same volume, etc

Label - Product - Art Paper Label - High-end wine

Make more art paper materials optional, to give the brand different experience and effect expression.

Make more art paper materials optional, to give the brand different experience and effect expression.

Label - Product - Metal Label - High-end wine

Wine label material in addition to special paper, film, can also use metal film

Concave and convex sense, strong three-dimensional sense, can be used for roll machine labeling

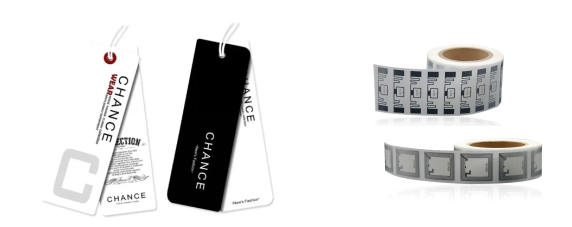

Tags - Products -RFID tags and tags

RFID operation process automation, reduce human error and personnel costs, provide real-time and correct information, establish product history, high imitation cost, can be combined with the company's product data background, anti-counterfeiting, anti-cross goods and so on

At the same time, it can increase the photoelectric effect and provide interaction with consumers.

Tag - Sustainability

Materials such as rSG Paper FSC®*, PE (rPE) with recycled materials, PP (rPP) with recycled materials, PET (rPET) with recycled materials, PET release film (rPET) with recycled materials, and wash separation labels have been developed.

Help brands to complete carbon reduction, reduce the use of native resin, recyclable gold design principles.