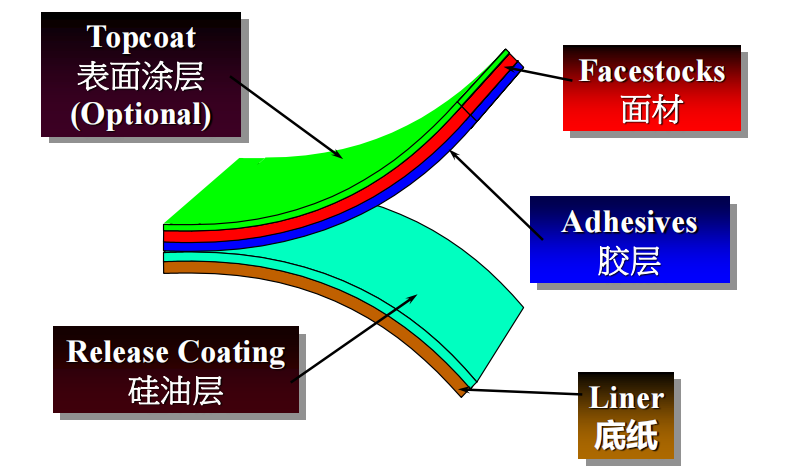

In the world of product packaging and branding, adhesive labels play a crucial role. These labels not only convey important information but also enhance the visual appeal of products, helping them stand out on crowded shelves. The effectiveness of adhesive labels largely depends on the quality of the materials used. Let's delve into the key materials that form the foundation of high-quality adhesive labels.

一. Face Material: The First Impression

The face material of an adhesive label is the surface that carries the printed design, logo, or text. It’s the first thing a customer sees and touches, making its quality paramount. Common materials for the face include:

- Paper: Widely used for its versatility and cost-effectiveness. It can be coated, uncoated, or treated for various finishes, making it suitable for a range of products from food packaging to luxury items.

- Film: Offers durability and resistance to water and chemicals, making it ideal for products exposed to harsh environments, such as industrial goods or outdoor products.

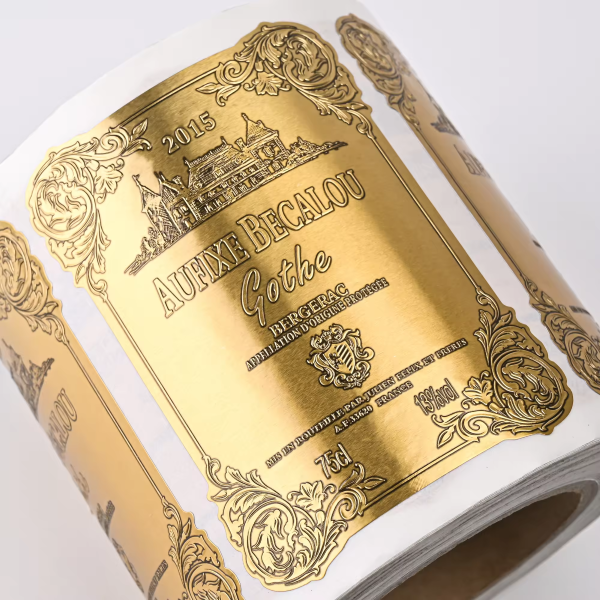

- Metal Foil: Adds a premium feel to labels, often used in high-end products like wine bottles and cosmetics.

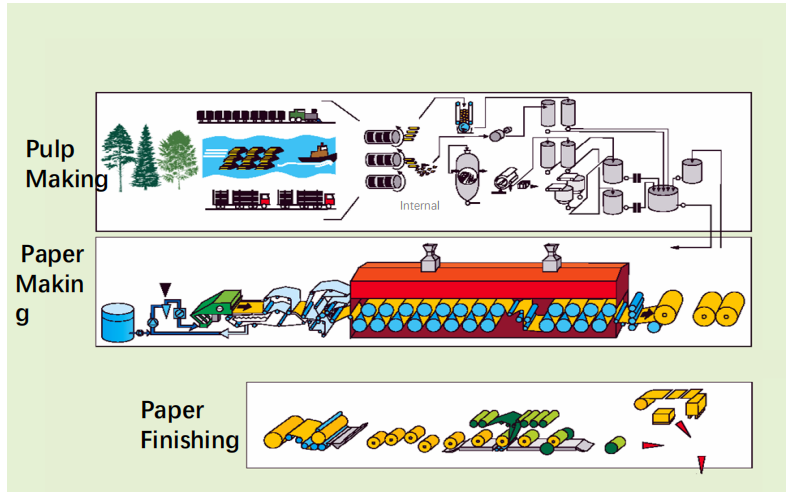

1. Paper Material

Common types of paper products:

1)Wood Free Paper: Also known as writing paper, this type of paper is free from mechanical pulp, providing a smoother surface.

2)Art Paper (Semi-Gloss Paper):

This paper is treated to give a smoother surface than wood-free paper, making it ideal for high-quality printing.

3)Mirror Coat Paper (High Gloss White):

A more refined version of art paper, this paper has undergone additional surface treatment to enhance its glossiness, resulting in a bright and shiny finish.

4)Other Types of Paper:

Includes thermal paper, aluminum foil paper, and other specialized papers.

Advantages and Disadvantages of Paper, and Its Application in Industries

1. Advantages of Paper:

- Good Printability:

- Easy Availability: Paper is widely available and accessible in various markets.

- Cost-Effective: Compared to other materials, paper is often more affordable.

2. Disadvantages of Paper:

- Susceptibility to Liquids: Paper is easily damaged or degraded by exposure to liquids.

- Fragility: It can be easily torn or broken.

3. Main Applications:

- Pharmaceutical Labels, Product Barcodes: Paper is commonly used for labeling in the pharmaceutical industry and for printing product barcodes.

- Food & Beverage, Alcohol, Daily Goods: Paper is also widely used in industries such as food and beverage, alcohol, and daily consumer products due to its versatility and printability.

二. Adhesive: The Bonding Agent

The adhesive is the layer that binds the label to the product surface. Its quality ensures that the label remains intact throughout the product's lifecycle. There are different types of adhesives designed for specific applications:

1)Permanent Adhesive: Designed for labels that need to stay put, this adhesive forms a strong bond with the surface, ensuring durability and longevity.

2)Removable Adhesive: Allows labels to be removed without leaving residue, making it ideal for temporary promotions or reusable containers.

3)Specialty Adhesive: Tailored for specific needs, such as cold environments (for freezer labels) or highly textured surfaces (like rough cardboard).

三. Release Liner: The Protective Backing

The release liner is the backing material that protects the adhesive until the label is applied. It must allow for easy removal without compromising the adhesive layer. Common materials for release liners include:

- Glassine: A smooth, transparent paper that provides a cost-effective and reliable option for most applications.

- Polyester: Offers superior strength and is used when high-speed label application is required or when dealing with complex shapes.

四. Considerations for Choosing Materials

When selecting materials for adhesive labels, it's important to consider the product's environment, the surface to which the label will be applied, and the desired appearance. For instance, labels on products that will be exposed to moisture or varying temperatures should prioritize materials with high durability, such as film-based face materials and specialty adhesives.

五. The Role of Innovation

Advancements in material technology continue to enhance the performance of adhesive labels. Innovations such as eco-friendly adhesives and biodegradable face materials are now available, aligning with the growing demand for sustainable packaging solutions. Companies looking to stand out can leverage these materials to not only meet environmental standards but also to appeal to eco-conscious consumers.

Conclusion

The choice of materials in adhesive label production is critical to the label's performance, durability, and overall appeal. By understanding the properties of different materials and selecting the right combination, businesses can create labels that not only enhance their product's appearance but also ensure functionality across various conditions. As the industry evolves, staying informed about the latest material innovations can give brands a competitive edge in the marketplace.