Self-adhesive labels are versatile, easy-to-use labels. often referred to as "sticker labels," Due to their convenience and functionality. Self-adhesive have become a staple in various industries. Unlike traditional labels that require water or heat activation, self-adhesive labels come with a pre-applied adhesive, allowing them to stick to surfaces with just a press, no additional glue or equipment needed.

What are Self-Adhesive Labels?

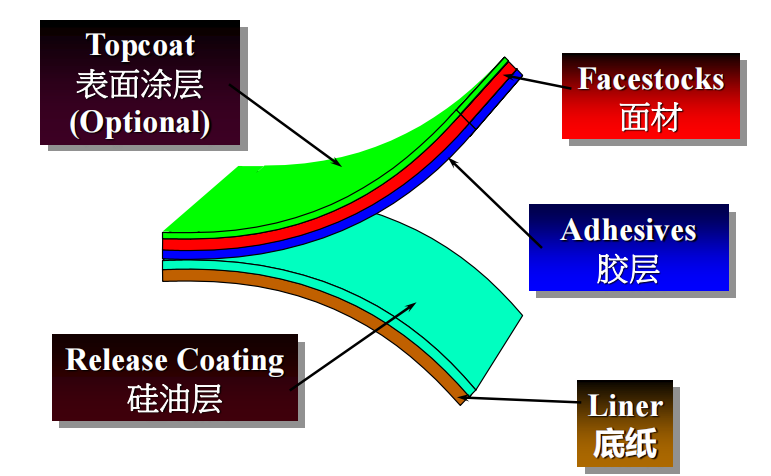

A self-adhesive label is a multi-layered structure typically composed of three primary components:

Face Material: The top layer that carries the printed information or design.

Adhesive Layer: A sticky layer that allows the label to bond to surfaces.

Release Liner: A backing paper that protects the adhesive until the label is ready to be applied.

These labels are widely used in packaging, logistics, retail, and many other sectors due to their ease of application and wide range of material options, such as paper, film, and foil.

Self-Adhesive Labels vs. Traditional Labels

Self-adhesive labels and traditional labels share similarities in terms of materials, usage methods, and application scenarios, but they also have key differences.

1. Similarities:

Identification Function: Both types are used for identification, information transmission, or decoration. Whether it's product identification, price tagging, or logistics labeling, their basic functions are similar.

Material Diversity: Both self-adhesive and traditional labels can be made from various materials such as paper, plastic, metal, or fabric.

Printing Techniques: Both can utilize various printing techniques such as offset printing, digital printing, and screen printing to achieve different patterns and text effects.

2. Differences:

- Adhesion Method:

Self-Adhesive Labels: These come with a pre-applied adhesive, requiring only the removal of the release liner to apply—no additional adhesive or equipment needed.

Traditional Labels: Typically do not have adhesive backing and require other tools or materials (like glue, staples, or string) to be attached.

- Ease of Use:

Self-Adhesive Labels: Extremely user-friendly, they can be quickly applied and removed, making them ideal for scenarios that require large-scale, fast operations, such as logistics and retail.

Traditional Labels: May require additional steps like applying glue or securing with fasteners, making them less convenient.

- Suitable Scenarios:

Self-Adhesive Labels: Widely used in situations requiring quick application, such as product packaging, food labels, pharmaceutical labels, and logistics tags.

Traditional Labels: More commonly used in long-term or specialized scenarios, such as book labeling, name tags, and product hang tags.

- Removal:

Self-Adhesive Labels: Some are designed to be removable, while others may leave residue when removed.

Traditional Labels: Since they lack adhesive, they usually do not leave residue, though the removal process may involve handling additional materials like glue.

In summary, self-adhesive labels offer greater operational convenience, making them suitable for large-scale, rapid application scenarios. Traditional labels, on the other hand, may be better suited for long-term applications or scenarios requiring more flexible usage. Such as book Labels, product hang tags, name tags, hang tags, and more.

Storage Considerations for Self-Adhesive Labels

Proper storage is crucial to maintaining the quality and performance of self-adhesive labels. Below are some key considerations:

Characteristics of Self-Adhesive Labels:

Self-adhesive labels are composed of a multi-layered structure, including the release liner, adhesive, and face material. Different paper and film materials react differently to external temperature and humidity.

Effects of High Temperature and High Humidity:

- Temperature: Storing labels at excessively high temperatures can cause adhesive

seepage at the die-cut edges, leading to issues such as poor label release or adhesive overflow during application.

Humidity: High humidity environments can cause labels to absorb moisture, resulting in curling, ink smudging, and wrinkling.

Effects of Low Temperature and Low Humidity:

Cold Conditions: Storing self-adhesive materials in cold environments, especially outdoors, can damage the adhesive, leading to reduced stickiness and poor processing characteristics if not properly conditioned before use.

Low Humidity: In low-humidity environments, the release liner may lose moisture, causing the label material to curl and making application difficult.

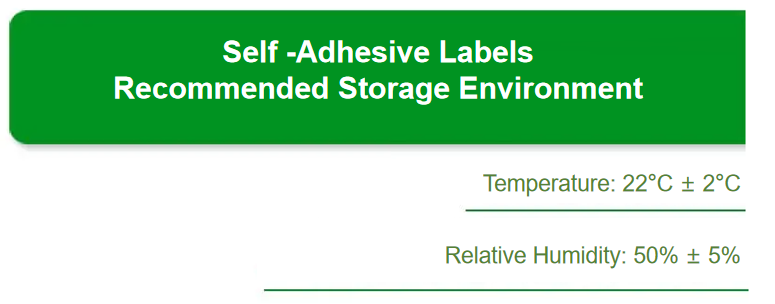

Recommended Storage Environment:

Temperature: 22°C ± 2°C

Relative Humidity: 50% ± 5%

It is advised not to place the materials directly on the floor or against walls. The intact packaging creates a closed environment that protects the self-adhesive label materials. For unopened materials, the humidity control requirements can be slightly relaxed (recommended storage temperature 15~28°C, relative humidity 40%~60%). However, it's important to follow the first-in, first-out principle, and ensure that unused materials are kept in their original packaging.

By adhering to these storage guidelines, you can ensure that your self-adhesive labels retain their quality and are ready for use whenever needed.