We produce various types of film-based adhesive labels, which are applied to a wide range of products available in the market. The commonly used film types include:

- PE (Polyethylene)

- BOPP (Polypropylene)

- PVC (Polyvinyl Chloride)

- PET (Polyester)

- Synthetic Paper

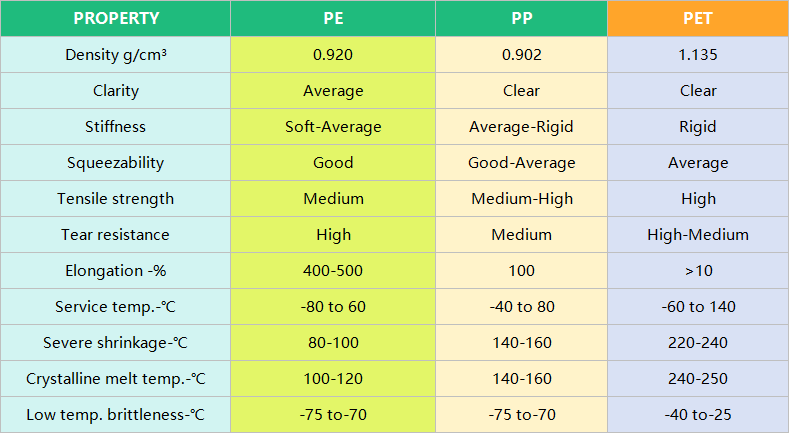

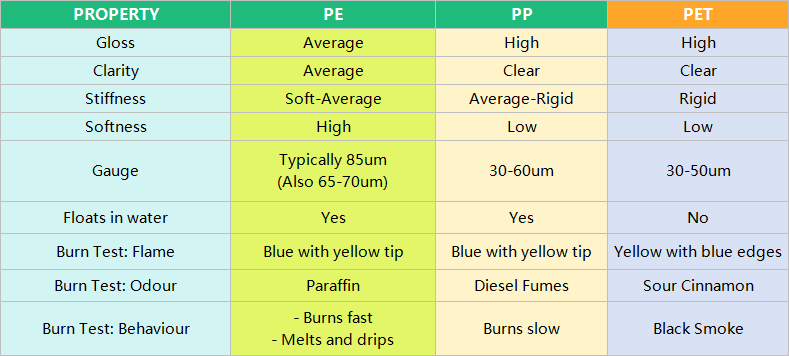

PE (Polyethylene)

Polyethylene, also known as Polythylene or polythene and abbreviated as PE, is a milky white, semi-transparent to opaque thermoplastic resin. It is odorless, non-toxic, with a wax-like texture, and exhibits excellent low-temperature resistance and chemical stability, making it resistant to most acids and alkalis. PE is commonly used in food bags, packaging boxes, and the pharmaceutical industry.

However, PE materials have poor tolerance to high temperatures, strong acids, and strong alkalis.

Common Issues with PE Labels:

- Dyne Value Degradation

- Low Strength and Tear Resistance

- Poor High-Temperature and Weather Resistance

- Relatively Low Material Stiffness

Solutions:

- Utilize inline corona treatment as early as possible.

- Pay attention to tension control during printing and processing to avoid material deformation caused by overheating.

- Increase the tension of the backing paper during labeling and use a small-angle label dispensing plate.

PP (Polypropylene)

PP /PE paper is a type of synthetic paper made by mixing polypropylene (PP) resin, polyethylene (PE) resin, and nano-level mineral powder. It is known for its good wear resistance, heat resistance, and oil resistance. It is lightweight, strong, tear-resistant, with good printability, opacity, UV resistance, durability, and environmentally friendly characteristics. PP is widely used in the food, medical, and cosmetic industries.

Common Issues with PP Labels:

- Dyne Value Degradation and Ink Adhesion Issues

- Surface Pinholes

- Low Rigidity of Low-Weight Face Materials

Solutions:

- Adjust the printing process.

- Avoid using on irregular or particularly soft bottles.

- For low-weight face materials, consider laminating or combining them with other materials.

PVC (Polyvinyl Chloride)

PVC, short for Polyvinyl Chloride, is a high molecular material obtained through the addition polymerization reaction of vinyl chloride. It is the third most widely produced synthetic plastic polymer, after polyethylene and polypropylene. PVC exhibits excellent aging and weather resistance.

Common Issues with PVC Labels:

- PVC requires the addition of additives or plasticizers for usability, which may pose health risks, such as disrupting biological endocrine functions or increasing cancer risk. Children chewing on these soft plastic toys may face safety concerns due to additive leaching.

- PVC releases harmful substances at high temperatures, causing environmental pollution. Due to these concerns, environmental protection groups like Greenpeace advocate for a global phase-out of PVC, leading to restrictions in certain countries and regions.

However, PVC is still used illegally due to its low cost.

PET (Polyester)

PET, or Polyethylene Terephthalate, is a type of polyester resin and is commonly referred to as thermoplastic polyester. PET has excellent optical properties, weather resistance, and outstanding abrasion resistance, dimensional stability, and electrical insulation. PET bottles are widely used for beverages and rigid food packaging due to their high strength, transparency, non-toxicity, impermeability, lightweight, and high production efficiency.

Common Issues with PET Labels:

- Ink Adhesion Issues

- Thermal Transfer Printing Issues

- Adhesive Bleeding After Die-Cutting

Solutions:

- It is recommended to use materials with surface coating treatments.

- Pre-test with PET-specific ink and compatible ribbons (and avoid contact with organic solvents).

- Use sharp die-cutting blades and hard backing pads.

Synthetic Paper

Synthetic paper is a material made from synthetic resin with characteristics similar to regular paper. It is typically made from biaxially oriented polypropylene (BOPP) or high-density polyethylene (HDPE). Applications include label paper (which can bond with ink) and non-label paper. Synthetic paper is highly waterproof, flexible, durable, and tear-resistant.

Common Issues with Synthetic Paper Labels:

- Surface Coating Adhesion

- Relatively Stiff Material

Solutions:

- Control the viscosity of the ink.

Avoid using on irregular or particularly soft bottles.